Abstract

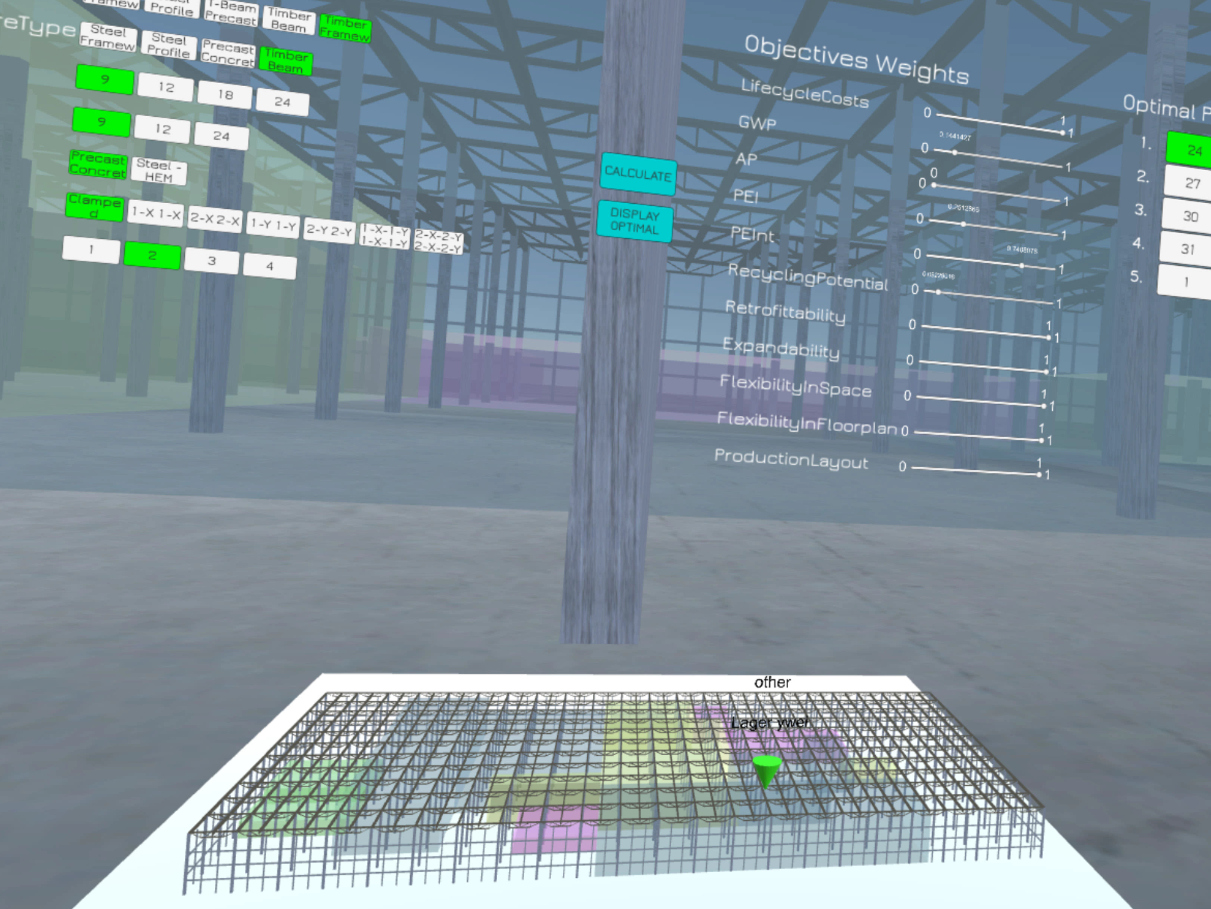

Due to product individualization, customization and rapid technological advances in manufacturing, production systems are faced with frequent reconfiguration and expansion. Industrial buildings that allow changing production scenarios require flexible load-bearing structures and a coherent planning of the production layout and building systems. Yet, current production planning and structural building design are mostly sequential and the data and models lack interoperability. In this paper, a novel parametric evolutionary design method for automated production layout generation and optimization (PLGO) is presented, producing layout scenarios to be respected in structural building design. Results of a state-of-the-art analysis and a case study are combined to develop a novel concept of integrated production cubes and the design space for PLGO as basis for a parametric production layout design method. The integrated production cubes concept is then translated into a parametric PLGO framework, which is tested on a pilot-project of a hygiene production facility to evaluate the framework and validate the defined constraints and objectives. Results suggest that our framework can produce feasible production layout scenarios which respect flexibility and building requirements. In future research the design process will be extended by the development of a multi-objective evolutionary optimization process for industrial buildings to provide flexible building solutions that can accommodate a selection of several prioritized production layouts.

Reference

Reisinger, J., Zahlbruckner, M. A., Kovacic, I., Kán, P., Wang-Sukalia, X., & Kaufmann, H. (2021). Integrated multi-objective evolutionary optimization of production layout scenarios for parametric structural design of flexible industrial buildings. Journal of Building Engineering, 46(103766), 103766. https://doi.org/10.1016/j.jobe.2021.103766